Packing is an important aspect of any product based industry. Packing attracts the customers and consumers towards the product. A well packed product is said to have more sales than others due to consumer attentiveness of the product.

Packing takes more than 12% of the manufacturing cost of the products. Even the pharmaceutical industry is not spared from these costs. Also, the packing in pharmaceutical industry is more crucial because they have to secure the medicine till the time of use. It is not just an attractive cover but a protective over cover.

Different types of packing are seen in the pharma industry. Blistering is one of the most common type used in the packing of tablets.Blister packing provides an authenticity to the packed product and also acts as a tamper proof.

Packing takes more than 12% of the manufacturing cost of the products. Even the pharmaceutical industry is not spared from these costs. Also, the packing in pharmaceutical industry is more crucial because they have to secure the medicine till the time of use. It is not just an attractive cover but a protective over cover.

Different types of packing are seen in the pharma industry. Blistering is one of the most common type used in the packing of tablets.Blister packing provides an authenticity to the packed product and also acts as a tamper proof.

The integrity of the product is protected using the unit-packing using such machine. It is easy and simple to pack tablets using a blister packing machine. Let us see the method of blistering and also the advantages of having a blister packing machine.

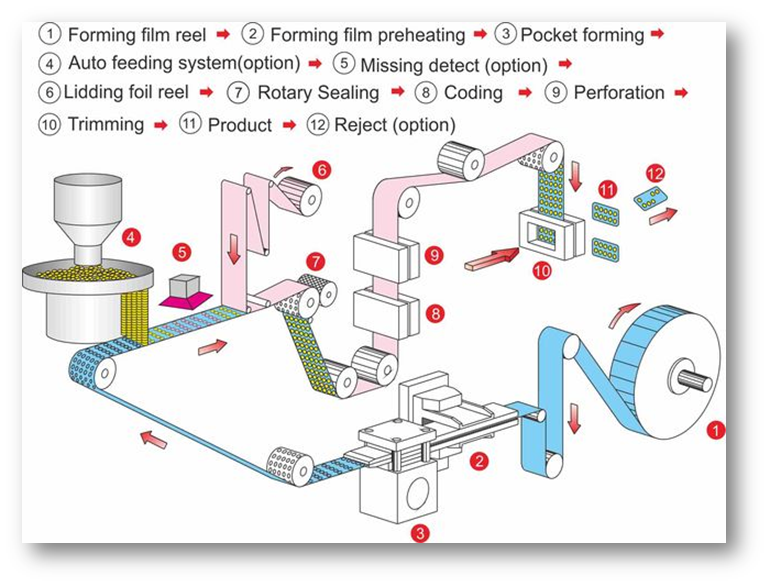

How Does The Blister Packing Machine Works?

Blister packing is done with a concept called as the FFS (form fill and seal). In some countries this is also called as the PTP (Push through Pack). The process is quite simple to the way it is described.

In the first part of the blister packing machine, rolls of flat plastic and other packing materials is present which rolls through the machine as the process proceeds. The materials to be packed are also passed through the machine in such a way that they are in between the plastic covers.

Blister packing is done with a concept called as the FFS (form fill and seal). In some countries this is also called as the PTP (Push through Pack). The process is quite simple to the way it is described.

In the first part of the blister packing machine, rolls of flat plastic and other packing materials is present which rolls through the machine as the process proceeds. The materials to be packed are also passed through the machine in such a way that they are in between the plastic covers.

This complete setup containing lengths of plastic rolls with tablets and other to-be-packed materials between them is passed from the work piece of the blister packing machine.

The machine seals the material in between the covers as it passes through. This process looks too obvious to be termed as a special packing called blister packing. But, it has the advantage that some air gets embedded within the pack and allows the tablets or capsules being packed to be in a suspended atmosphere along with air making the pack tamper proof while transport.

If the packing was done without the product in between the plastic sheets, it looks as if blisters are formed on a thick plastic sheet using a thin plastic skin. That is why this mode of packing is called blister packing and the machine is called blister packing machine.

It is easy to operate this packing machine and can be used also for packing consumer goods other than the pharmaceutical products. So, if one ideates to start small packing firm, having a blister packing machine is a must.

The machine seals the material in between the covers as it passes through. This process looks too obvious to be termed as a special packing called blister packing. But, it has the advantage that some air gets embedded within the pack and allows the tablets or capsules being packed to be in a suspended atmosphere along with air making the pack tamper proof while transport.

If the packing was done without the product in between the plastic sheets, it looks as if blisters are formed on a thick plastic sheet using a thin plastic skin. That is why this mode of packing is called blister packing and the machine is called blister packing machine.

It is easy to operate this packing machine and can be used also for packing consumer goods other than the pharmaceutical products. So, if one ideates to start small packing firm, having a blister packing machine is a must.

RSS Feed

RSS Feed